Is it true that polymer barriers are bad for the environment?

By

Helder Figueiredo

·

2 minute read

By

Helder Figueiredo

·

2 minute read

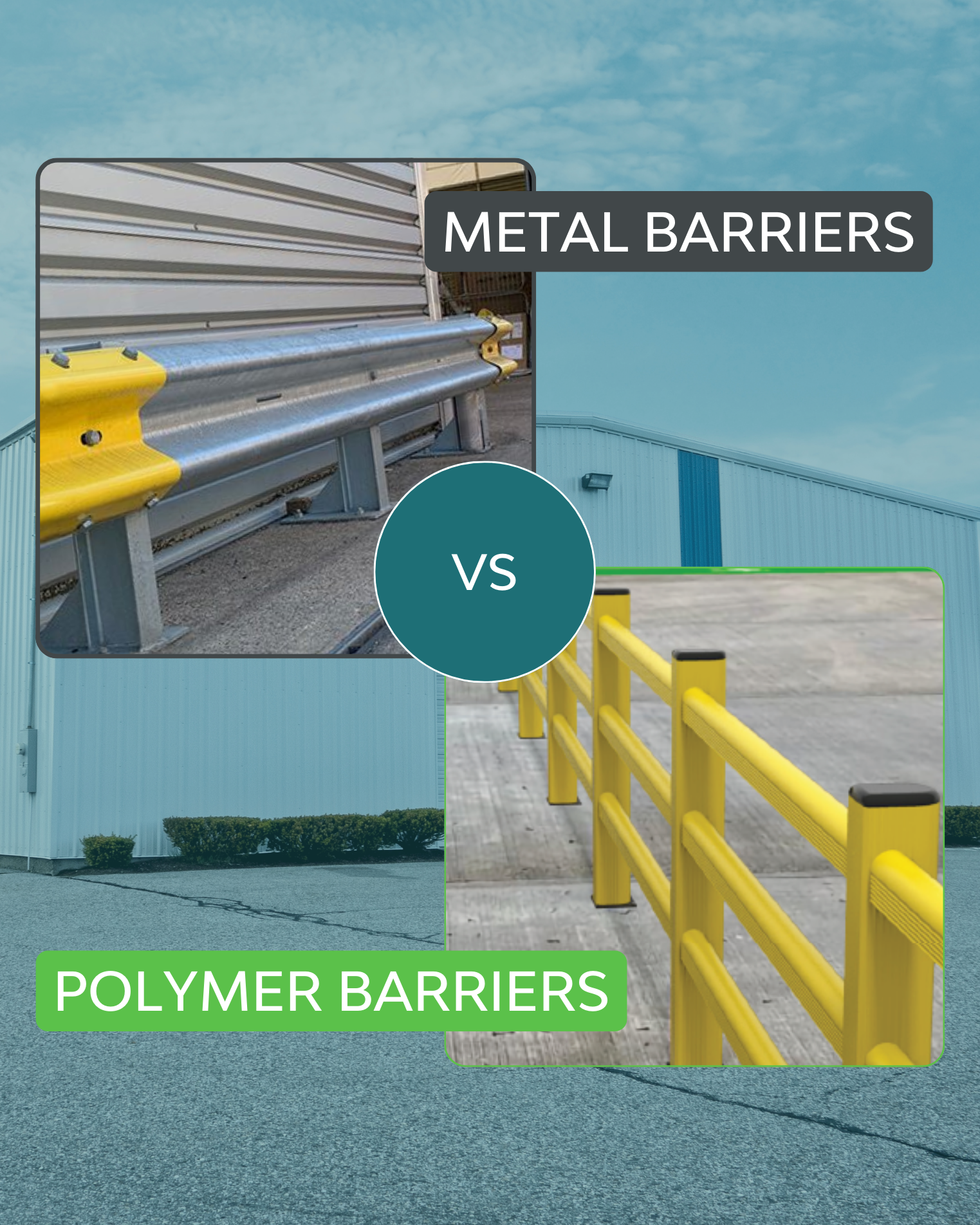

In the world of workplace safety, polymer barriers have become a go-to solution for pedestrian segregation and vehicle impact protection. However, a common question we hear is: Are polymer barriers bad for the environment?

It’s a fair concern. When people hear "polymer," they often associate it with plastic waste, pollution, and environmental harm. But the reality is far more nuanced. While some forms of plastic have a negative environmental impact, modern polymer safety barriers are designed with sustainability in mind - offering long-term environmental benefits over traditional alternatives like steel.

So, let’s break down the myths and facts about polymer barriers, their environmental footprint, and why they are actually a sustainable choice for businesses looking to improve safety without compromising on ESG goals.

Why do some people think polymer barriers are bad for the environment?

It’s understandable why some businesses hesitate when they hear “polymer.” Here are the most common concerns:

- Plastics contribute to pollution - Many people worry that polymer barriers are made from single-use plastics or materials that are difficult to recycle.

- Steel is seen as ‘greener’ - Some assume that steel barriers are the more eco-friendly option because steel is a widely recycled material.

- Manufacturing impact - Traditional plastic production has a reputation for being energy-intensive, leading to concerns about carbon emissions.

But are these concerns accurate when it comes to polymer barriers? Not exactly. Let’s explore why they are actually a sustainable alternative.

The reality: Why polymer barriers are good for the environment

Closed-loop manufacturing: Zero waste to landfill

Unlike traditional plastic products, polymer barriers are designed with a circular economy in mind. Our main supplier, MPM, operates a closed-loop production system—this means:

✔️ They reuse all waste materials in their own production process

✔️ They generate their own electricity, reducing reliance on fossil fuels

✔️ They achieve zero waste to landfill, ensuring minimal environmental impact

This process ensures that polymer barriers are not single-use plastics; they are engineered to be durable, reusable, and sustainable.

Energy-efficient production vs. steel barriers

Steel is a recyclable material, but its production requires an immense amount of energy and resources. The process of mining iron ore, smelting, and manufacturing steel barriers has a high carbon footprint compared to polymer production.

Polymer barriers, by contrast:

✔️ Require less energy to manufacture

✔️ Produce fewer carbon emissions than steel fabrication

✔️ Do not require frequent repainting or galvanisation, which adds to steel’s environmental impact

In many cases, the total lifetime carbon footprint of a polymer barrier is lower than that of a steel alternative.

Longer lifespan = Less waste

Steel barriers are prone to rust, bending, and permanent damage after impacts. This means they often need full replacements—which leads to more material waste and increased production demand.

Polymer barriers, however:

✔️ Absorb impact and return to shape, reducing the need for replacements

✔️ Require minimal maintenance, eliminating waste from repaints and repairs

✔️ Last significantly longer, reducing overall material consumption

By choosing polymer barriers, businesses reduce waste generation and lower their long-term environmental footprint.

So, are polymer barriers a sustainable choice?

Yes. While plastic waste is a legitimate concern in many industries, polymer barriers are not the problem - in fact, they’re part of the solution.

By choosing high-quality, long-lasting polymer barriers from Clarity, businesses benefit from:

✔️ Zero waste to landfill from our closed-loop manufacturing

✔️ Lower energy consumption compared to steel barriers

✔️ Minimal maintenance & replacements, reducing long-term waste

✔️ Future-proof solutions that integrate advanced safety technology

Want to learn more about sustainable workplace safety? Download our PAS 13 Brochure today to see how our barriers help businesses stay compliant while reducing environmental impact.

Considering polymer barriers for your site? Get in today to discuss the most cost-effective, eco-friendly solution for your business.

.jpeg)