Why Every Warehouse Needs a Pedestrian Safety System with Integrated Signage

By

Alana Graham

·

5 minute read

By

Alana Graham

·

5 minute read

When warehouse pedestrian safety systems fail, the consequences are catastrophic.

Recent HSE prosecutions show the devastating impact of outdated approaches - just in November 2024, a company was fined £400,000 after a worker suffered multiple leg fractures when struck by a forklift. The employee now has a metal plate in their leg for life.

Yet most facilities still rely on painted lines and static signage instead of integrated safety systems.

Modern warehouse pedestrian safety systems with integrated LED signage are revolutionising how UK facilities protect their workers. These systems combine physical barriers, smart sensors, and real-time visual warnings to prevent accidents before they happen.

If you're serious about pedestrian safety, legal compliance, and protecting your people from life-changing injuries, this guide will show you why integrated signage systems are becoming the new standard:

-

Why Do Most Warehouse Pedestrian Crossings Fail When You Need Them Most?

-

What Does UK Legislation Actually Require for Pedestrian Crossings?

-

How Do Modern Pedestrian Crossings Prevent Accidents Before They Happen?

-

Which Integrated Signage Systems Provide the Strongest Protection?

-

How Can You Implement Fail-Safe Crossings Without Disrupting Operations?

Why Do Most Warehouse Pedestrian Crossings Fail When You Need Them Most?

The honest answer? Because they're designed for compliance, not safety.

Most crossings rely on painted lines, basic signage, and the assumption that everyone will see them and follow the rules. But in busy warehouses, that assumption kills people.

HSE guidelines make it clear: crossing points must be "suitably marked and signposted" with "barriers or rails to prevent pedestrians from crossing at dangerous points." Yet the majority of warehouse accidents happen at crossings that technically met basic requirements.

The three fatal flaws of traditional crossings:

Visibility failure - Painted lines fade, get covered in dust, or become invisible in poor lighting. Static signs lose visual impact after just three days as workers become "sign blind".

Timing failure - There's no communication between pedestrians and forklift drivers about when it's safe to cross. People guess, drivers assume, and accidents happen.

Enforcement failure - Without physical or technological controls, crossings depend entirely on human behaviour. And humans make mistakes.

An incident in 2022 involving logistics company William Stobart shows the consequences: a worker lost both legs below the knee after the company "failed to ensure this area of the warehouse was organised so that vehicles and pedestrians were segregated and circulated in a safe manner." The £160,000 fine pales beside the human cost.

What Does UK Legislation Actually Require for Pedestrian Crossings?

The legal requirements are stronger than many facilities managers realise.

Under the Workplace (Health, Safety and Welfare) Regulations 1992, crossing points must be "clearly marked, protected, and equipped, and their use should be enforced." This isn't a suggestion - it's the law.

HSE's three pillars for crossing safety:

Separation - Pedestrians and vehicles must be kept separate "wherever possible" using "guard rails or fencing where appropriate."

Clear identification - Crossings require "clear identification" potentially including "traffic lights, zebra markings or other such systems."

Visibility - Pedestrians and drivers must have "adequate visibility" with barriers positioned to prevent crossing "where visibility is reduced."

What does best practice look like?

- Physical barriers to prevent unsafe crossing

- Clear signage visible in all lighting conditions

- Systems that actively manage crossing timing

- Controls that enforce safe behaviour rather than hoping for it

How Do Modern Pedestrian Crossings Prevent Accidents Before They Happen?

The most effective crossings don't just mark where to cross - they actively manage when it's safe to do so.

LED projected crossings use sensors to detect forklift trucks and project a stop sign to pedestrians when vehicles are present. When clear, they project a zebra crossing indicating it's safe to cross.

Why sensor-activated crossings work:

Real-time communication - Both pedestrians and drivers receive instant, clear information about crossing safety. No mixed signals.

Impossible to ignore - The dramatic switch from zebra crossing to stop sign "cannot be missed" unlike static signage that becomes background noise.

Self-enforcing - The system creates a physical and visual barrier to unsafe behaviour. Pedestrians instinctively stop when they see the projected stop sign.

Our case study at Altecnic demonstrates this in practice:

After installing integrated pedestrian barriers with gates and LED floor markings, they achieved complete segregation between pedestrian routes and forklift traffic. The combination of physical barriers and smart signage eliminated the guesswork that causes accidents.

The key components that make crossings fail-safe:

- Motion sensors detect approaching vehicles before pedestrians can see them

- LED projections provide unmistakable visual warnings directly onto the crossing

- Safety gates create physical barriers that open only when safe

- Integration with existing warehouse management systems for total coordination

Which Integrated Signage Systems Provide the Strongest Protection?

The strongest protection comes from layering physical and technological controls that work together.

Level 1: Smart LED projections

LED projected floor markings eliminate the maintenance cycle of traditional paint, lasting up to five years without fading. They're particularly effective in food and pharmaceutical environments where frequent cleaning destroys painted markings within weeks.

Applications:

- FLT warning projections that alert pedestrians to approaching vehicles

- Zebra crossings that activate only when safe

- Stop signs projected directly onto pedestrian routes

- Speed limit warnings for forklift operators

Level 2: Automated pedestrian gates

Physical gates that integrate with LED signage create the strongest protection. Our Safeway Gate system prevents pedestrians from entering forklift routes until sensors confirm it's safe.

Our automated pedestrian priority crossing demonstrates this integration in action. By combining barriers, traffic lights, and sensor technology, the system gives pedestrians safe, controlled passage while maintaining efficient vehicle flow. Drivers only stop when necessary, but when pedestrians need to cross, they have complete priority - just like a pelican crossing.

Level 3: Complete integration

The most advanced systems integrate crossing management with:

- Vehicle speed monitoring

- Loading bay coordination

- Shift change traffic management

- Emergency response systems

HSE warehouse guidance specifically mentions managing "periods where the number of vehicles or pedestrians moving along traffic routes change, eg when office staff arrive or leave, or when shifts change."

How Can You Implement Fail-Safe Crossings Without Disrupting Operations?

The biggest barrier to upgrading crossings? The fear of operational disruption.

Modern modular systems solve this challenge completely.

Phase 1: Smart signage installation

LED projected systems can be installed above active walkways without touching the floor. They're ideal for leased warehouses or frequently changing layouts because they don't require permanent floor modifications.

Installation typically takes:

- Half-day for single crossing LED projection

- 1-2 days for multiple integrated crossings

- No operational downtime required

Phase 2: Physical barrier integration

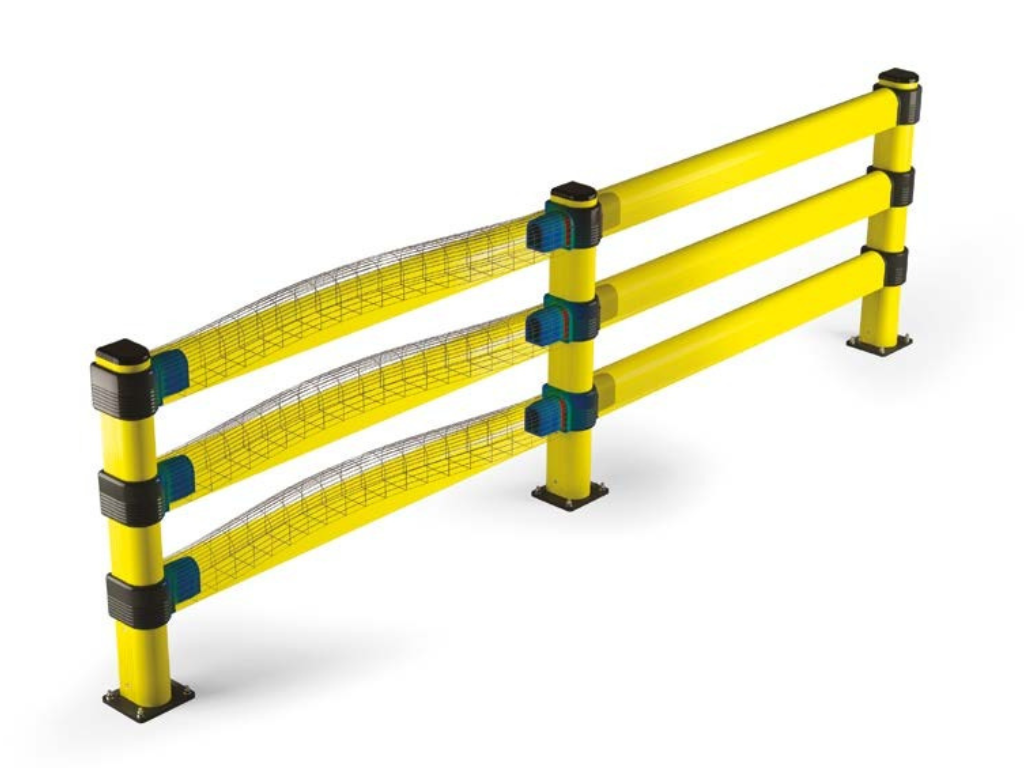

Polymer safety barriers can often be installed during live operations. Unlike traditional steel barriers requiring hot works, polymer systems use mechanical fixings that don't disrupt workflow.

The modular approach means:

- No permanent floor changes

- Easy reconfiguration as operations evolve

- Integration with existing safety systems

- Immediate compliance with PAS 13 standards

Phase 3: System integration

Advanced crossings can integrate with warehouse management systems, automatically adjusting for:

- Peak traffic periods

- Delivery schedules

- Maintenance activities

- Emergency procedures

ROI calculation for smart crossings:

Traditional paint crossings cost £200-500 per crossing annually in repainting and maintenance. LED projected systems last five years with minimal maintenance, typically paying for themselves within 18 months.

More importantly, avoiding a single serious accident saves far more than the system cost. Recent HSE fines range from £30,000 to £400,000 for pedestrian safety failures - before considering compensation claims and reputational damage.

Ready to Create Crossings That Actually Protect Your People?

Half-measures don't stop accidents. They just make them someone else's responsibility when they happen.

With workplace transport accidents causing 14 recorded fatalities in 2024/25, the pressure for genuine pedestrian protection has never been higher.

The smart money isn't on better paint - it's on systems that actively prevent accidents before they can happen.

At Clarity Safety, we've helped facilities across the UK eliminate pedestrian crossing accidents by combining intelligent LED signage with proven physical barriers.

Ready to see how fail-safe signage would work in your facility?

Book your free site assessment - we'll show you exactly how to eliminate crossing accidents while maintaining operational efficiency.