Metal Barriers vs Polymer Barriers: What’s the Difference?

By

Alana Graham

·

2 minute read

By

Alana Graham

·

2 minute read

If you’re planning to upgrade or replace warehouse safety barriers, one of the biggest decisions you’ll face is choosing between metal (typically steel) and polymer barrier systems.

At Clarity, we supply and install both options — so we don’t just sell one and dismiss the other. Our goal is to help you make the right decision based on your needs, risks, and long-term safety goals. So, what’s the real difference between these barrier types? And which is right for your factory?

Let’s break it down.

What is a steel barrier?

Steel barriers are a familiar sight across the UK — especially in industrial settings and along motorways. Most warehouse steel barriers are galvanised, mounted directly to the concrete floor, and serve a “blocking” function. They’re typically strong and rigid, designed to stop a vehicle rather than absorb the impact.

Steel systems have been a mainstay for decades. But technology and safety standards have evolved.

What is a polymer barrier?

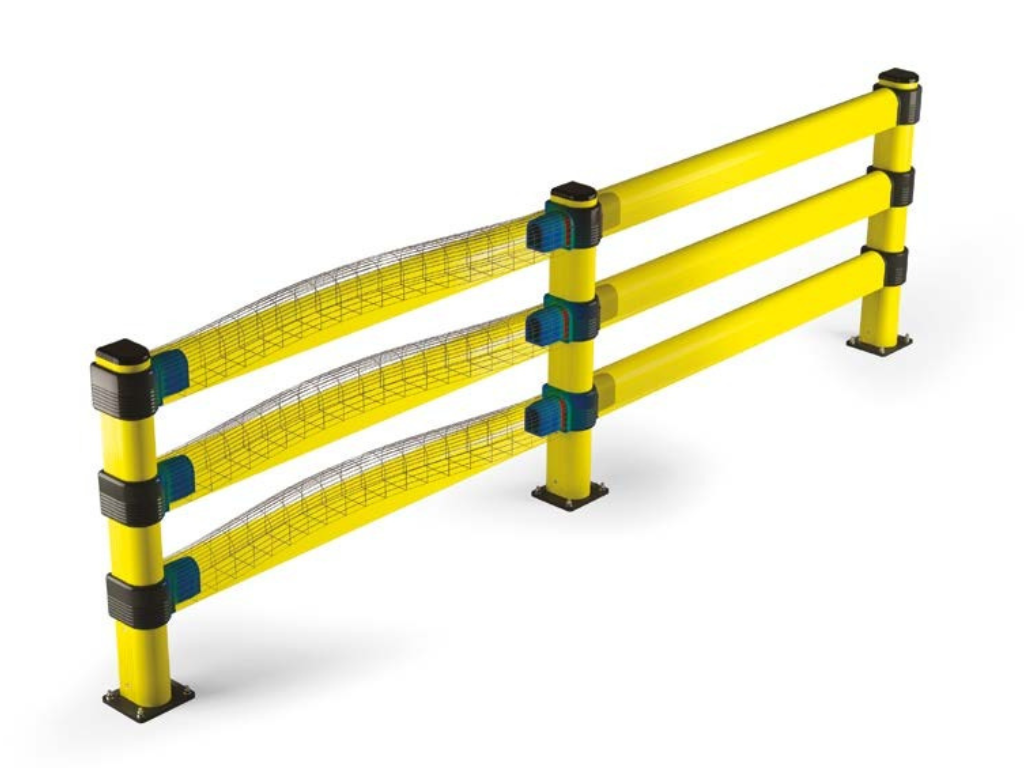

Polymer (or plastic) barriers are engineered from high-performance materials like HDPE, polypropylene, or in the case of MPM polymer barriers, modified PVC.

Unlike steel, polymer barriers are impact-absorbing. On impact, they flex and deform temporarily, dissipating energy before returning to their original shape. That means less damage to the floor, vehicle, and barrier — and fewer repairs and replacements over time.

They’re often modular, highly visible, and increasingly preferred by companies focused on reducing downtime and improving the clarity of pedestrian segregation.

Benefits of steel barriers

Steel systems still offer several advantages:

-

Lower initial material cost

-

Custom colour options via painting or powder coating

-

Easy to source from UK stockists for fast repairs

-

Familiar “one-size-fits-all” approach - no impact calculations needed

For sites with existing steel systems or where temporary protection is needed, steel may still be a cost-effective short-term solution.

But be aware: steel barriers are only cheaper if they’re never hit. One strong impact can cause floor damage, bent steel, or forklift repairs; which costs significantly more than a flexible solution.

Benefits of polymer barriers

Flexible polymer barriers offer a smarter, safer approach for modern sites:

-

Impact absorption reduces damage to floors, vehicles, and the barrier itself

-

Minimal maintenance — no repainting, no corrosion

-

Long-term cost savings on repairs and replacements

-

High visibility with bright colours built into the material

-

Cleaner appearance — especially with wipeable, non-porous PVC

-

More sustainable – uses less energy to produce and is fully recyclable

-

Modular designs allow for easy reconfiguration and minimal disruption during layout changes

Looking to test polymer in your environment? Try a small installation first and see the difference.

So, which is right for you?

There’s no universal answer. It depends on your traffic volume, layout complexity, safety priorities — and how much downtime you’re willing to risk.

✅ Steel may suit static areas or legacy setups.

✅ Polymer is the better choice for high-traffic zones, forklift segregation, and sites prioritising safety, flexibility, and appearance.

Not sure what a factory fit out costs with a new barrier system? See our pricing here, download our barrier guide or get in touch to arrange a call or site survey with one of our safety barrier specialists.