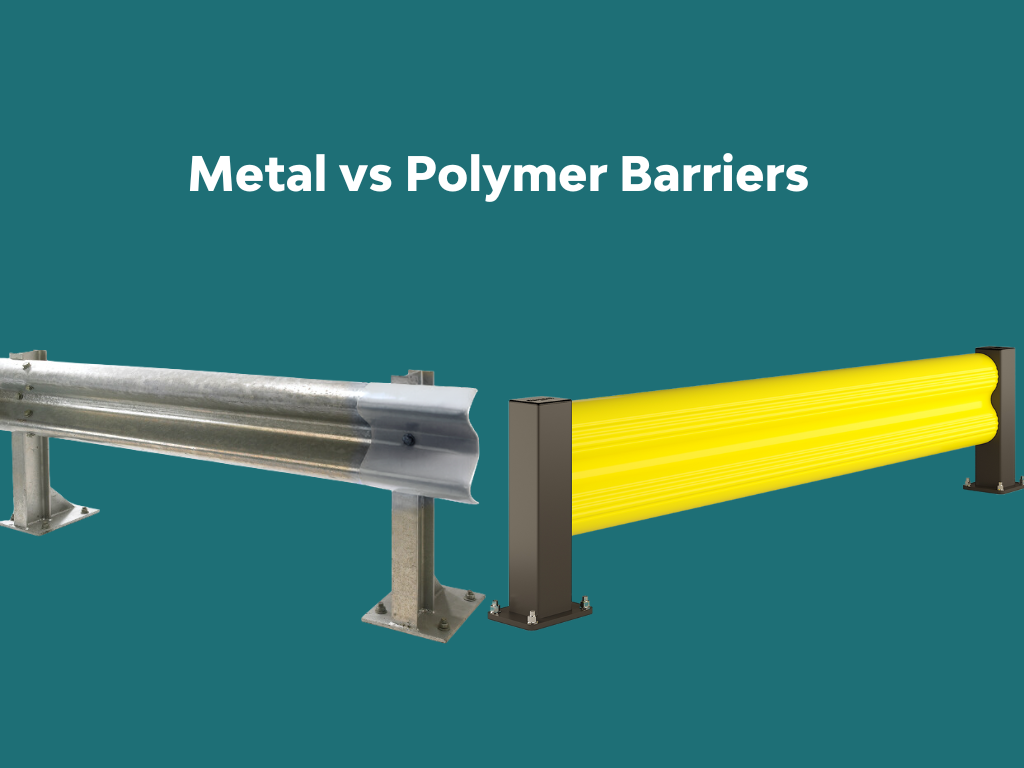

Why Should I Choose Polymer Barriers Instead of Metal Barriers?

By

Damian White

·

3 minute read

By

Damian White

·

3 minute read

If you’re responsible for maintaining a busy warehouse or industrial site, you know that safety barriers are essential. But choosing the right type of barrier can be a real challenge. One of the most common questions we hear is:

“Should I choose polymer barriers or metal barriers for my facility?”

It’s a valid question, after all, steel barriers have been the industry standard for decades. But as technology advances and safety requirements evolve, polymer safety barriers are emerging as a more reliable, cost-effective and sustainable alternative.

In this article, we’ll break down why polymer barriers often outperform metal barriers and why they might be the smarter choice for your facility.

Contents:

- The Problem with Metal Barriers

- Why Polymer Barriers Are the Smarter Choice

- Real-World Applications: Where Polymer Barriers Outperform Metal

- How to Choose the Right Barrier for Your Needs

The Problem with Metal Barriers

Steel barriers may look strong and durable, but they come with a range of challenges that aren’t always obvious at first glance. Here are some of the most common issues logistics and H&S managers face with metal barriers:

-

High Maintenance Costs: Steel barriers are prone to rust and corrosion, especially when used outdoors. This means frequent repainting and maintenance to keep them in good condition.

-

Permanent Damage: Steel barriers don’t absorb impact. Instead, they transfer the collision force directly to vehicles, infrastructure, and the floor, causing costly damage.

-

Risk of Injury: When a steel barrier bends or breaks, it can create sharp edges or become a trip hazard, posing further risks to employees.

-

Expensive Replacements: Once a steel barrier is compromised, it often needs a complete replacement, adding to long-term costs.

While steel barriers may seem like a solid choice, their drawbacks can end up costing more than you expect, both in maintenance and safety risks.

Why Polymer Barriers Are the Smarter Choice

Polymer barriers are designed to solve the problems associated with steel, offering a modern, durable, and flexible solution. Here’s why they are quickly becoming the preferred option for industrial safety:

1. Absorbing Impact Instead of Transferring It

Unlike steel barriers that transfer impact energy, polymer barriers are engineered to flex and absorb collisions. This means:

-

Reduced Vehicle Damage: Instead of causing dents or structural harm, polymer barriers cushion the blow.

-

Less Floor Damage: The flexible nature means that impact force is not transferred to the floor, preventing cracks and expensive floor repairs.

-

Safer for Employees: No sharp edges or broken pieces after a collision.

2. Maintenance Made Easy

Steel barriers often require regular upkeep to prevent rust and corrosion. Polymer barriers, on the other hand, are:

-

Corrosion-Resistant: Ideal for both indoor and outdoor use, with no risk of rust.

-

UV-Stable: Colour stays vibrant, even in direct sunlight.

-

Low Maintenance: No need for repainting or surface treatments.

By choosing polymer barriers, you reduce maintenance costs and eliminate the hassle of constant repairs.

3. Cost Savings Over Time

While polymer barriers may have a higher upfront cost, the long-term savings are significant:

-

Reduced Maintenance: No repainting or rust-proofing required.

-

Fewer Replacements: The barriers are durable enough to withstand repeated impacts.

-

Lower Risk of Downtime: Less chance of barriers being out of service due to damage.

4. Sustainable and Environmentally Friendly

One common misconception is that polymer barriers are bad for the environment. In reality, they are designed with sustainability in mind:

-

Closed-Loop Manufacturing: Our barriers are made with minimal waste and are 100% recyclable.

-

Energy-Efficient Production: Less energy-intensive than manufacturing steel barriers.

-

Extended Lifespan: Fewer replacements mean less waste going to landfill.

Real-World Applications: Where Polymer Barriers Outperform Metal

Polymer barriers are suitable for both internal and external environments, making them versatile and reliable across various applications:

-

Loading Docks and Warehouses: Reduce vehicle damage and maintenance costs.

-

Pedestrian Walkways: Improve visibility and reduce injury risk with bright, corrosion-resistant barriers.

-

Outdoor Perimeters: UV-stable and rust-free, even in harsh conditions.

Discover more about our Polymer Safety Barriers and how they can improve safety in your workplace.

How to Choose the Right Barrier for Your Needs

If you’re still unsure about whether polymer or metal barriers are the best fit for your facility, consider the following:

-

What are the primary risks in your environment?

-

Do you need barriers that can withstand harsh outdoor conditions?

-

Are ongoing maintenance and repair costs becoming an issue?

At Clarity, we’re here to help you make the right decision. We offer a range of polymer safety barriers that are designed to meet the toughest industry standards while providing long-term savings and enhanced safety.

Need Expert Advice? Contact Us Today!

Choosing the right barrier can make a significant difference in safety and cost efficiency. If you’d like to discuss your specific needs or see how polymer barriers could benefit your site, get in touch today to speak with one of our safety experts!