Should I Choose Modular or Fixed Barriers for My Factory?

By

Alana Graham

·

2 minute read

By

Alana Graham

·

2 minute read

Choosing the right barrier system for your facility is about more than just impact ratings or price. One of the most important questions to ask early on is:

"Should I install modular barriers or fixed barriers?"

Whether you're fitting out a new site, upgrading outdated steel, or simply reconfiguring your warehouse flow, the decision between modular and fixed systems will shape your site’s flexibility, future costs, and downtime.

In this article, we break down the differences between the two and help you decide which is right for your factory or warehouse.

What’s the Difference Between Modular and Fixed Barriers?

Let’s start with a simple definition:

-

Fixed barriers are set lengths of metal or polymer, typically cut and installed to fit a specific space. Once in place, they’re difficult to move or reconfigure without specialist tools or additional components.

-

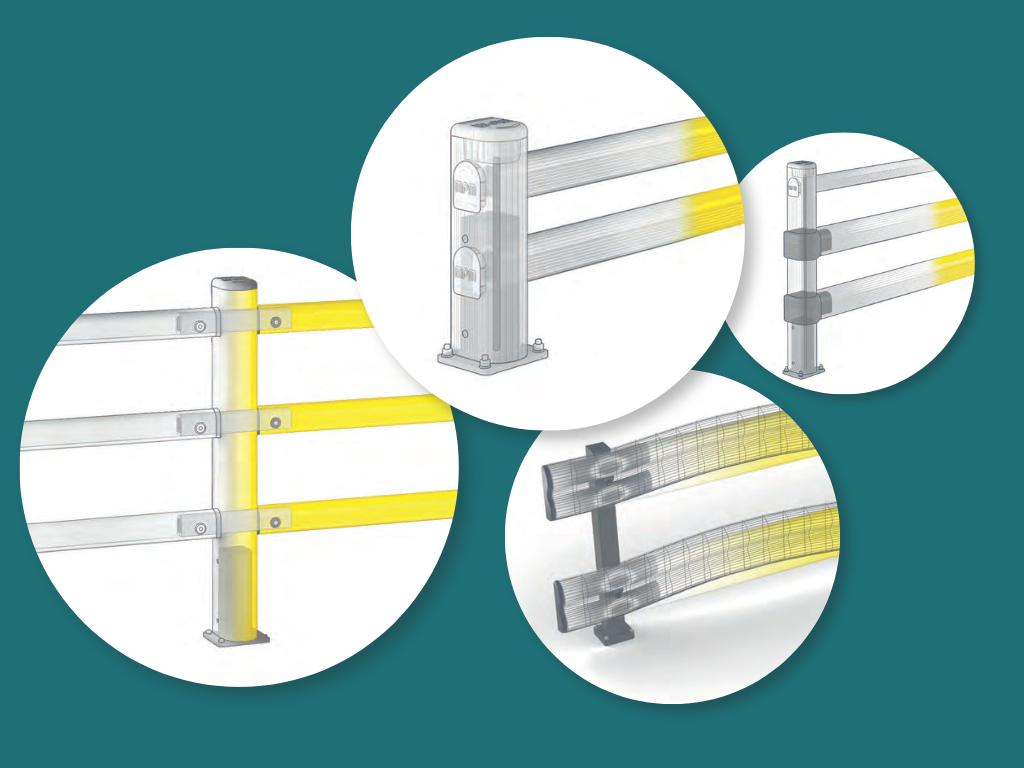

Modular barriers use a system of interchangeable posts and rails that can be cut or adjusted on site. The rails slot into place and can be removed, resized, or repositioned as your layout evolves.

Think of fixed barriers like fitted furniture, designed for permanence.

Modular systems are more like adjustable shelving, made for change.

Why Choose Modular Barriers?

At Clarity, most of the modern sites we work with are now moving towards modular barrier systems. Here’s why:

More Flexible Layouts

Modular barriers let you change, extend, or reconfigure without starting from scratch. This is ideal for factories with seasonal layouts, frequent process changes, or growing operations.

Lower Long-Term Costs

While modular systems may be slightly more expensive up front, they’re far more cost-effective in the long run. You can reuse existing components, adjust layouts yourself, and avoid major reinstall projects.

Faster Installation

On-site cutting and adaptable post spacing means faster install times — which can reduce downtime and disruption.

Easy Repairs

If a rail is damaged, you replace just the rail. With fixed systems, you may need to replace whole sections or call in a contractor.

Ideal for Projects in Phases

Planning to install barriers across the site in multiple phases? Modular systems allow you to expand over time without mismatch or rework.

Explore our modular barrier options here.

When Might Fixed Barriers Be a Better Fit?

That said, there are situations where fixed barriers may still be suitable, particularly in environments where:

The layout is unlikely to change

If your factory has permanent fixtures, clearly defined lines, and little-to-no expected change, a fixed system may meet your needs.

Maximum rigidity is required

Some very specific zones - like racking protection or loading bay buffers - may still benefit from a fixed barrier if there’s no risk of reconfiguration.

Key Considerations Before You Decide

Still unsure which option is right for you?

Here are a few quick questions to ask:

-

How often does your layout or process flow change?

-

Will your team want to make barrier adjustments themselves?

-

Are you planning to install everything in one go, or in phases?

-

Would removing a section in future be a headache or an opportunity?

If your site is dynamic, evolving, or in constant motion, modular barriers are often the smarter long-term investment.

Need advice on choosing the right system?