How to Break a Barrier Install into 3 Budget-Friendly Phases – UK Workplace Safety Guide

By

Alana Graham

·

2 minute read

By

Alana Graham

·

2 minute read

Safety shouldn’t be a luxury.

When budgets are tight - but people’s safety is on the line - what do you do?

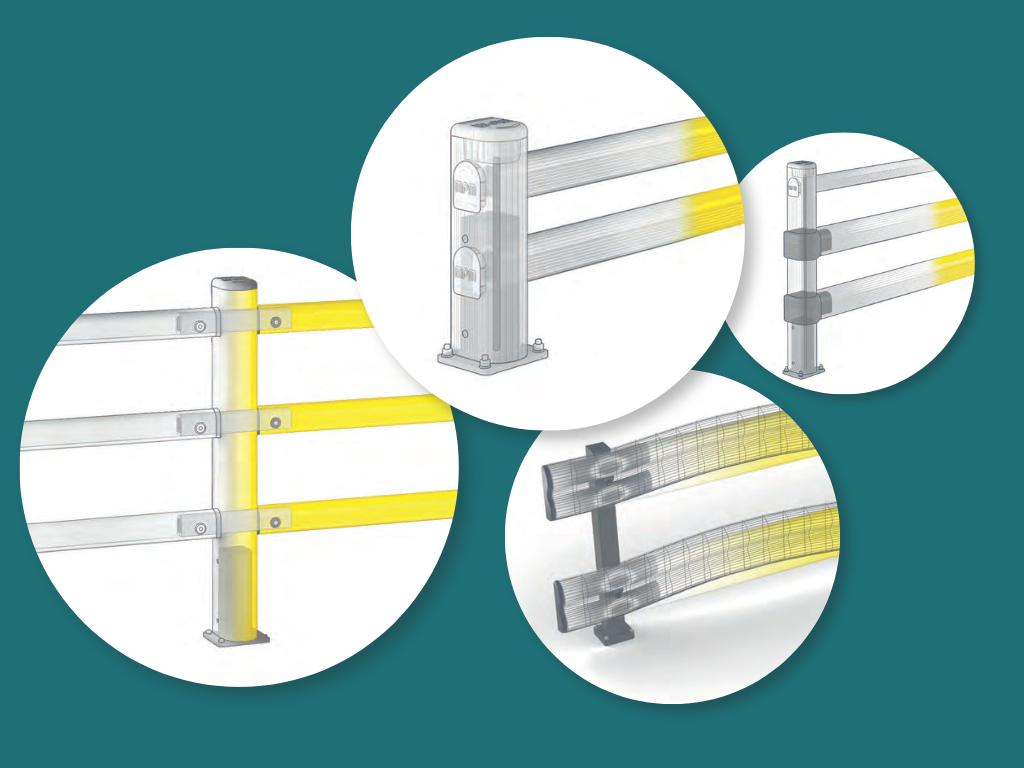

If you’re running a UK warehouse, factory, or distribution centre, you’ve probably faced this dilemma: you need safety barriers, but capital spending is being closely scrutinised. That’s exactly why a phased safety barrier installation is such an effective approach.

A budget-friendly barrier installation lets you:

- Act fast where the risk is highest.

- Spread your investment across months or quarters.

- Build a safer, more compliant site - without halting your operations.

We’ve seen this model work for teams across the UK. Here’s how to do it right:

-

Phase 1: Affordable Warehouse Safety Starts with the Danger Zones

-

Phase 2: Protect Your High-Cost Assets Next In Your Phased Barrier Installation

-

Phase 3: Achieve Full-Site Safety and Compliance with UK Regulations

Quick Summary

A budget-friendly barrier installation can be completed in three phases:

|

Phase 1 |

Fast protection of high-risk zones (people). |

|

Phase 2 |

Strategic defence of expensive infrastructure. |

|

Phase 3 |

A complete safety system that meets UK regulations. |

Phase 1: Affordable Warehouse Safety Starts with the Danger Zones

Goal: Cut risk fast by protecting the highest-exposure areas.

Start with the people zones. These are your pedestrian crossings, forklift intersections, loading bays. The places where someone has said, "That was close."

Installing polymer safety barriers in high-risk zones is the single fastest way to reduce incident rates, insurance claims, and operational downtime. This stage often delivers the quickest barrier project ROI.

One warehouse manager told us,

"We figured racking was the priority. Then a forklift brushed past our main pedestrian lane. No injuries, but it shook us. That’s when we realised: people come first."

Your Phase 1 Checklist:

- Map where pedestrians and vehicles cross paths.

- Flag areas with past collisions or near-misses.

- Prioritise loading bays, narrow aisles, and main thoroughfares.

Phase 2: Protect Your High-Cost Assets Next In Your Phased Barrier Installation

Goal: Protect expensive infrastructure from avoidable hits.

Once your people are protected, move on to infrastructure: racking, dock levellers, electrical panels. The stuff that gets expensive fast when damaged.

In Phase 2, expand your affordable warehouse safety network to shield these assets. This reduces downtime, repair bills, and maintenance headaches while boosting long-term barrier project ROI.

Your Phase 2 Checklist:

- Audit structures at risk: rack ends, columns, panels.

- Add machine guards and rack-end barriers.

- Shield loading dock gear with protective zones.

In the Midlands, one manufacturer cut £14,000 in annual repair costs by securing just two key machine areas.

Phase 3: Achieve Full-Site Safety and Compliance with UK Regulations

Goal: Ensure total site safety and full legal compliance.

You’ve covered the big-ticket items. Now it’s time to close the gaps and create a seamless safety environment. Think back-of-house corridors, dead-end zones, and overlooked areas.

This stage unifies your barrier system visually and physically - showing employees, auditors, and HSE inspectors that safety is embedded in your culture.

Your Phase 3 Checklist:

- Link all barrier zones into one continuous system.

- Cover low-traffic and warehouse perimeter areas.

- Add high-vis markings, signage, and bollards.

This phase supports full alignment with HSE workplace transport safety guidance, particularly the legal duty to separate pedestrians from vehicles.

Why This Phased Barrier Installation Works

Breaking your barrier installation into stages gives you:

- Budget flexibility – spread spend over multiple periods.

- Fast ROI – see risk reduction from day one.

- No disruption – keep the site moving.

- Culture shift – safety becomes habit, not headache.

From Aberdeen to Southampton, UK businesses are using this approach to reduce incidents, protect assets, and strengthen compliance records.

Ready to Make a Smart Safety Move?

Whether you’re facing urgent risks or planning a full-site strategy, Clarity can help.

Book Your Site Safety Review – We’ll assess your site, map high-impact zones, and create a phased safety barrier installation plan tailored to your risks and budget.