What is the Safest Pedestrian Walkway Barrier?

By

Alana Graham

·

5 minute read

By

Alana Graham

·

5 minute read

A painted line on the floor isn't enough to protect people.

While painted walkways might look organised, they offer zero protection when a 3-tonne forklift loses control. HSE statistics show that 14 people were killed after being struck by moving vehicles in the workplace during 2024/25.

Workplaces can no longer afford to treat walkway barriers as an afterthought. The question isn't whether you need barriers - it's whether yours will actually protect people when it matters most.

At Clarity, we've spent over a decade helping UK facilities design pedestrian protection systems that combine PAS 13-aligned polymer barriers with smart technology. Because true safety isn't only about compliance - it's about creating walkways that deliver genuine protection.

In this guide, we'll explore:

What is the Purpose of a Pedestrian Walkway Barrier?

A pedestrian walkway barrier serves three critical functions: physical separation between people and vehicles, guided traffic flow, and clear visual safety cues.

Think of it as the difference between a suggestion and a safeguard. Painted lines suggest where people should walk. Proper barriers actively protect them from vehicles that drift, drivers who don't see pedestrians, and the inevitable human errors that happen in busy facilities.

According to HSE data, around 5,000 people are injured in workplace transport accidents. Many of these incidents occur because temporary or visual-only solutions failed under real-world conditions.

Paint lines, tape, and cones might meet basic 5S requirements, but they don't meet the fundamental test: Will this protect someone when a forklift driver is distracted, tired, or operating in poor visibility?

A truly safe barrier protects people, operations, and assets. It absorbs impact energy, maintains pedestrian routes even after being struck, and provides clear guidance that both drivers and pedestrians can follow instinctively.

What are the 5 Core Features of the Safest Pedestrian Barriers?

Does Your Barrier Meet PAS 13 Compliance Standards?

PAS 13:2017 is the gold standard for UK workplace safety barriers. Created by BSI with input from HSE and leading companies like DHL, Mars, and Network Rail, it's not mandatory but represents industry best practice.

PAS 13 states that safety barriers are needed between walkways and vehicle routes if they are closer than 1 metre and not separated by a raised kerb. This seemingly simple rule has profound implications for warehouse layout and legal compliance.

The code provides specific guidance on:

- Impact testing methodology with verified joule ratings

- Barrier positioning based on vehicle weight and speed

- Mandatory 5% safety factor for all calculations

- Documentation requirements for compliance audits

When evaluating suppliers, ask: "Can you provide independent test certificates showing PAS 13 compliance?" Many claim compliance without proper third-party verification.

Learn more about PAS 13: What is PAS 13? Your Guide to Workplace Barrier Compliance

Can Your Barriers Absorb Impact and Return to Position?

Steel barriers look strong, but strength isn't the same as safety. When a forklift hits rigid steel, the impact energy transfers to floor fixings, often causing:

- Cracked concrete around anchor points

- Bent barriers requiring replacement

- Damage to both the vehicle and floor

- Costly downtime for repairs

Polymer barriers work differently. They're designed with energy absorption technology that flexes on impact, then returns to position. This approach:

- Protects the floor from damage

- Reduces vehicle repair costs

- Maintains barrier integrity after multiple strikes

- Eliminates the maintenance cycle of steel systems

Our polymer systems have been tested to absorb impacts up to 10,000 joules while maintaining structural integrity - enough to stop a 2-tonne forklift travelling at walking speed.

How Visible Are Your Barriers in Real Operating Conditions?

High-visibility isn't just about bright colours. True visibility means barriers remain noticeable across all shifts, lighting conditions, and levels of dust or debris.

Key visibility factors include:

- Consistent colour contrast that works in artificial lighting

- Reflective elements for areas with moving lights (like forklift headlamps)

- Clean, non-porous surfaces that don't accumulate dust or grime

- Integrated LED systems for high-risk zones or poor lighting areas

Traditional steel barriers often use painted finishes that fade, chip, and become less visible over time. Polymer barriers maintain colour consistency throughout their lifespan and can integrate with LED Projected Floor Markings for enhanced visibility.

Are Your Barriers Positioned at Safe Distances?

Even the best barrier fails if it's installed incorrectly. PAS 13 provides detailed guidance on minimum clearances, with pedestrian walkways requiring at least 1 metre clear width, though 1.2 metres is recommended for wheelchair accessibility.

Proper positioning considers:

- Vehicle turning radii and typical drift patterns

- Pedestrian desire lines to prevent shortcuts through dangerous areas

- Sight lines ensuring drivers and pedestrians can see each other at crossing points

- Emergency access requirements for evacuation routes

Installation isn't just about bolting barriers to the floor. It requires understanding traffic flow, risk mapping, and how people actually move through the space across all shifts.

Can Your System Adapt to Operational Changes?

Warehouses evolve. Racking moves, processes change, and traffic patterns shift. The safest barriers are modular systems that can be reconfigured without major disruption or reinstallation costs.

Modern polymer barriers use connecting systems that allow sections to be added, removed, or repositioned as needed. This flexibility means your safety investment grows with your operation rather than becoming obsolete when layouts change.

Steel systems, by contrast, are often custom-welded installations that require complete replacement when facilities reconfigure.

What Common Safety Mistakes Put People at Risk?

Even well-intentioned safety managers can unknowingly create hazards through common installation errors:

Using Metal Rails in Pedestrian Zones: Armco and steel barriers were designed for highways, not pedestrian areas. Their rigid construction can cause severe injury on contact and creates trip hazards from protruding anchor points.

Relying on Floor Markings Alone: Paint fades, tape peels, and neither offers impact protection. HSE guidance makes clear that physical segregation is the most reliable form of pedestrian protection.

Incorrect Barrier Height or Spacing: Barriers that are too low allow forklift forks to pass over them. Gaps that are too wide let people squeeze through at dangerous points. PAS 13 provides specific dimensional requirements to prevent these issues.

Poor Walkway Design That Forces Risky Shortcuts: If the official pedestrian route is significantly longer or more difficult than cutting across vehicle areas, people will take shortcuts. Effective design follows natural desire lines while maintaining protection.

Inadequate Crossing Points: HSE guidance requires that crossing points be suitably marked and signposted, with clear sight lines in all directions. Many facilities provide barriers but fail to create safe, convenient crossing zones.

Remember: Safety isn't just about materials - it's about understanding how people and vehicles interact in real operating conditions.

How Do Smart Safety Barriers Go Beyond Basic Protection?

The next generation of pedestrian safety combines physical barriers with intelligent technology to create responsive protection systems.

LED-Integrated Walkways: Instead of static floor markings, LED Projected Floor Markings create bright, maintenance-free guidance that remains visible in all lighting conditions. These systems can be programmed to show different routes for different shifts or operational modes.

Motion-Activated Warnings: Our systems can integrate sensors that detect approaching vehicles and activate warning lights or audible alerts to pedestrians in crossing zones.

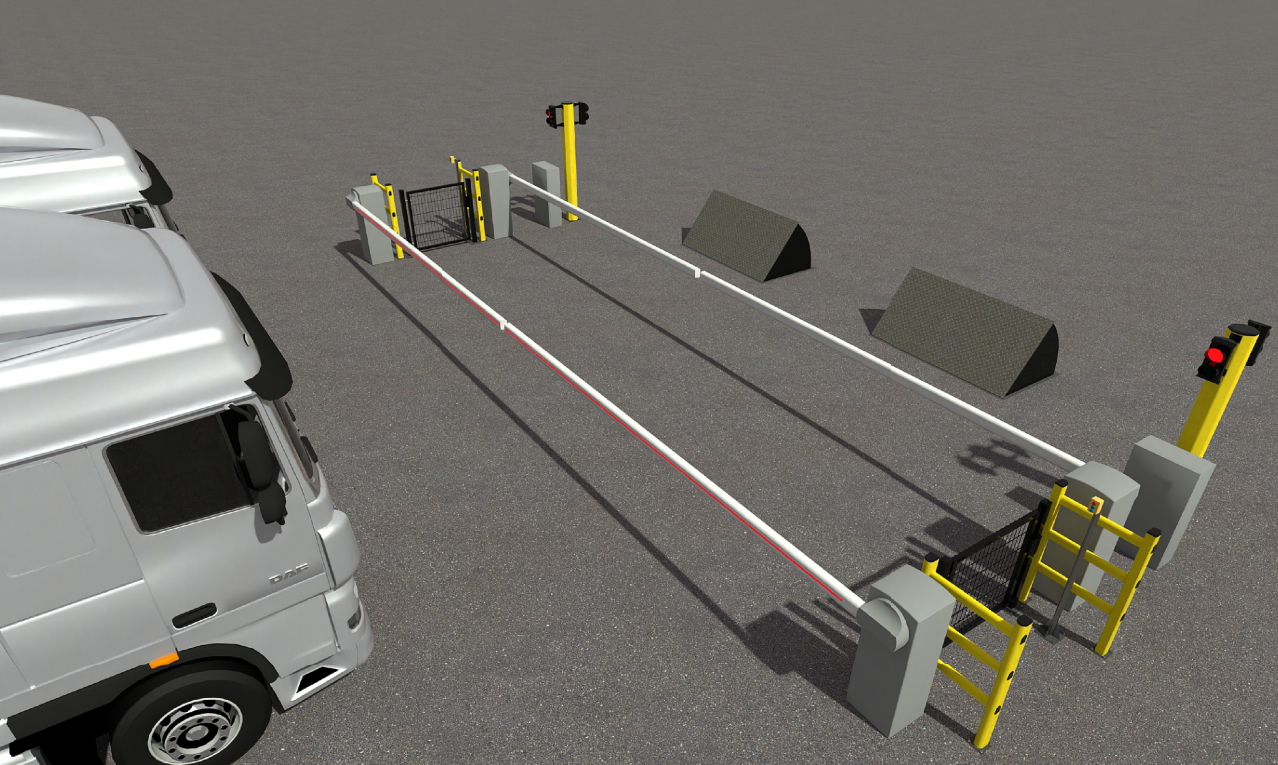

SafeWay Gate Technology: Our intelligent crossing system allows pedestrians to activate LED walkways that are impossible for drivers to miss. The system ensures pedestrian priority while maintaining operational flow.

Impact Monitoring: Advanced barriers can now detect and log impacts, helping safety managers identify problem areas and track near-miss incidents before they become accidents.

These aren't just gadgets - they're proven technologies that major UK operators use to meet stringent safety requirements while maintaining operational efficiency.

How Do You Choose the Safest System for Your Site?

Start with a professional on-site assessment rather than trying to specify barriers from a catalogue. Every facility has unique traffic patterns, operational constraints, and risk factors that influence the optimal solution.

Clarity's approach begins with risk mapping and traffic flow analysis:

- Observe actual pedestrian and vehicle movements across all shifts

- Identify conflict points where people and machinery interact

- Map desire lines to understand natural traffic patterns

- Assess environmental factors like lighting, noise, and space constraints

- Evaluate existing infrastructure and compliance gaps

This discovery phase informs a bespoke safety design that addresses your specific challenges rather than applying generic solutions.

Key Questions to Ask Potential Suppliers:

- Can you provide independent PAS 13 test certification?

- Do you conduct on-site risk assessments before specifying barriers?

- What's the impact rating of your barriers in joules?

- How do you handle future layout changes or expansions?

- Can you integrate with existing safety systems?

Read more: Safety Barriers for Warehouses: What You Really Need to Know

Why is Safety Designed, Not Assumed?

At Clarity Safety, we don't just supply barriers - we partner with you to create safer, more efficient working environments. Our polymer safety barrier systems combine PAS 13 compliance, energy-absorbing technology, and modular flexibility to protect your people and your operations.

Ready to find out how safe your pedestrian walkways really are? Contact our safety specialists for a free assessment and discover why leading UK operators trust Clarity to protect what matters most.