Why Do Most 5S Programmes Fail Within 6 Months?

By

Alana Graham

·

5 minute read

By

Alana Graham

·

5 minute read

You launched a 5S programme. The kickoff was promising. Management bought in, employees attended the training, and those first few weeks showed real progress.

Three months later, tools are back in random drawers. The cleaning stations you installed are gathering dust. Your 5S audit scores are sliding backwards. You're firefighting the same disorganisation issues you had before the programme started.

We know how frustrating this feels. You invested time, budget, and political capital into workplace organisation. Your team put in the effort. Yet somehow, despite everyone's best intentions, things have drifted back to how they were. It's not your fault. Most 5S programmes face the same pattern.

In this article, we'll show you why 5S initiatives collapse within months, what the research tells us about failure rates in UK manufacturing, and how visual management systems create the structure that turns temporary improvement into lasting change.

Contents

How Common Is 5S Failure in UK Facilities?

Research into lean manufacturing initiatives consistently shows that 60-70% of 5S programmes fail to sustain improvements beyond the first year. The Manufacturing Advisory Service reported that lack of visual controls and standardised systems ranks among the top three reasons for 5S breakdown in British facilities.

This isn't about employee resistance or management commitment. Facilities with engaged leadership and willing teams still see 5S programmes deteriorate. The pattern appears across sectors: automotive manufacturing, food processing, pharmaceutical production, and logistics operations all report similar challenges with 5S sustainability.

The pattern is consistent: training people on Sort, Set in Order, Shine, Standardise, and Sustain doesn't automatically create systems that make those principles stick. Knowledge without infrastructure fails.

What separates the 30% of programmes that do succeed? They build visual accountability into their 5S system from day one.

Why Do Employees Revert to Old Habits?

Human behaviour follows the path of least resistance. When 5S relies purely on memory and discipline, it's competing against years of ingrained work patterns.

Consider what happens during a busy shift. An operator needs a specific spanner. The shadow board shows exactly where it belongs, but the spanner isn't there because someone from the previous shift didn't return it. The operator now faces a choice: spend five minutes searching, or grab a different tool and work around it.

They work around it. The job gets done. No immediate consequence appears.

Three weeks later, half the tools are in wrong locations. Audit scores drop. Management sends reminder emails about 5S standards. Operators feel lectured about problems they didn't create. Engagement drops further.

Rather than a motivation problem, it's a systems problem.

Research in behavioural psychology shows that sustainable habit change requires three elements: a clear trigger, an easy action, and immediate feedback. Traditional 5S training provides the knowledge but not the system that enables these three elements in daily operations.

Visual management systems make the correct behaviour the easiest behaviour. Shadow boards with tool outlines show immediately what's missing. Visual checklists on cleaning stations make the process obvious. Performance boards display whether yesterday's 5S audit identified issues.

The feedback loop becomes immediate and visual, not buried in a monthly report.

What's Missing When 5S Programmes Collapse?

Failed 5S programmes share common gaps. Understanding these patterns helps explain why good intentions alone don't create lasting change.

No Visual Accountability

Spreadsheets tracking 5S audit scores don't change daily behaviour. They're reviewed in management meetings, not referenced by the people doing the work. When standards exist only in documents or training presentations, there's no mechanism for teams to self-correct during operations.

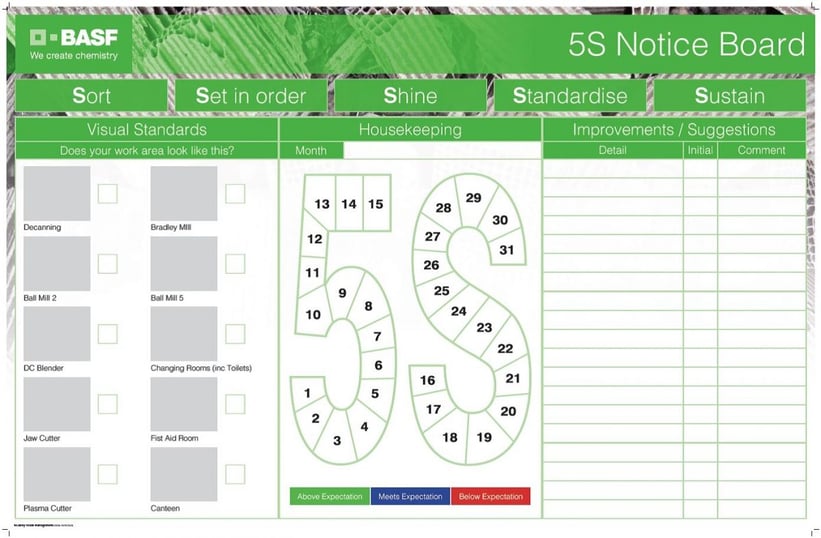

Successful programmes put accountability where work happens. Visual boards in work areas show current 5S status, trending performance, and specific actions needed. Everyone can see whether the area is maintaining standards without waiting for formal audits.

Missing Standardised Systems

"Put tools back where you found them" sounds clear until you realise different shifts organise tools differently. Without standardised locations marked visually, people create their own systems. Chaos follows.

Shadow boards, tool foam cut-outs, and clearly labelled storage create one standard that applies regardless of who's on shift. The system works because it removes ambiguity about where items belong.

Some facilities refer to their programme as "6S" rather than 5S, adding Safety as a sixth element to emphasise its importance. While this highlights safety's critical role, the reality is that effective 5S implementation already embeds safety throughout. Well-organised workplaces reduce trip hazards, prevent tool-related injuries, and create clear pedestrian routes away from forklift traffic. The terminology matters less than the outcome: proper workplace segregation that protects your team while maintaining efficiency.

Poor Team Engagement

5S programmes rolled out from management without involving shop floor teams rarely stick. Operators know their workflow better than anyone. When they're excluded from designing 5S systems, the resulting standards don't fit how work flows.

Visual management boards that teams update themselves create ownership. When operators track their own 5S scores and identify their own improvement actions, engagement increases. The programme becomes theirs, not something done to them.

How Does Visual Management Create Sustainable 5S?

Visual management transforms 5S from a temporary project into an integrated part of daily operations. It provides the physical systems that make good organisation the default option.

→ View our range of Visual Management Solutions.

Shadow Boards and Tool Storage

Shadow boards use tool outlines to show exactly where each item belongs. Missing tools are immediately obvious, not discovered during monthly audits. Teams can identify issues in real time and address them before they compound.

Foam cut-outs in tool boxes serve the same function. Operators see at a glance whether they have complete sets. This isn't about making things look tidy for audits. It's about creating systems where maintaining organisation requires less effort than letting things slide.

Cleaning Stations with Visual Standards

Cleaning stations that display the exact equipment needed and the cleaning process expected remove guesswork. New team members understand standards immediately. Experienced workers can verify they've completed tasks correctly.

These stations make the Shine element of 5S sustainable because the system shows what "clean" actually means in your specific operation. Visual standards replace vague instructions with clear examples.

Performance Boards That Drive Action

Visual management boards tracking 5S audit scores create accountability through transparency. When everyone can see current performance, trending results, and improvement actions, it changes team dynamics.

Stonegate Precision Tooling implemented visual managementboards alongside their 5S programme. Operations Manager Alan Pollard noted, "This is the first time we've had buy-in. It's what we need as a business operations department."

This resulted in their OTIF performance improving from 82% to 98%, with full team engagement through daily tiered meetings. The 5S programme didn't collapse because visual systems made maintaining standards part of normal operations, not an additional burden.

Read the full case study here → Case Study: Stonegate Precision Tooling

What Does Successful 5S Implementation Actually Look Like?

Jotun Paints faced exactly this challenge in 2017. Previous 5S initiatives had delivered minimal results. Employee engagement was low. Visual control across the site was practically nonexistent.

Working with Clarity's visual management consultants, they took a different approach. Rather than running another training programme and hoping for different results, they built visual systems that supported 5S as an ongoing process.

The transformation focused on creating visual accountability through custom magnetic overlay boards, standardised shadow boards for tool control, and performance tracking systems that teams could update themselves.

Five years on, the site achieved its goal of 10% efficiency improvement and became globally recognised as a truly lean and visual factory. Operational Efficiency Manager Natalie Hood explained: "Using Clarity meant we could see what other companies were doing and what was new in the market."

The programme succeeded because visual management made 5Ssustainable. It wasn't reliant on perfect discipline or constant management oversight. The systems themselves guided correct behaviour.

Read the full case study here → Case Study: Jotun Paints

Under the Management of Health and Safety at Work Regulations 1999, employers must ensure effective planning, organisation, control, monitoring, and review of preventive and protective measures. Visual management systems support these legal requirements by making workplace organisation auditable and measurable.

Can Your 5S Programme Avoid These Failures?

5S sustainability requires more than training and enthusiasm. It needs systems that make good organisation easier than disorganisation.

Visual management provides that system. Shadow boards show missing tools instantly. Cleaning stations standardise processes across shifts. Performance boards create accountability through transparency.

These aren't cosmetic improvements. They're the infrastructure that prevents 5S from becoming another failed initiative that everyone stops talking about after six months.

If your facility has tried 5S before without lasting success, the problem isn't your team's commitment. It's the absence of visual systems that sustain the programme when initial enthusiasm fades.

Ready to build 5S systems that stick?

Our visual management consultants can assess your current workplace organisation and recommend proven solutions. We'll show you how shadow boards, cleaning stations, and performance tracking systems turn temporary 5S projects into permanent operational improvements.

Contact our visual management team for a free site assessment.