What Are the Best Alternatives to A-Safe Barriers in the UK?

By

Alana Graham

·

4 minute read

By

Alana Graham

·

4 minute read

If you're reading this, you've probably been quoted by A-Safe and want to know what else is out there. Or maybe you've used their barriers before and are wondering whether you're getting the best deal for your next project.

Either way, you're not alone. We speak to warehouse and facilities managers across the UK every week who ask us exactly this question.

A-Safe has built a strong reputation over 40+ years, and for good reason. But they're not the only option, and depending on your priorities, they might not be the right fit. This guide breaks down the main alternatives, what makes each one different, and how to decide which supplier is best for your facility.

Contents:

- How Do the Barrier Materials Compare?

- What About Service and Support?

- How Do I Choose the Right Supplier for My Facility?

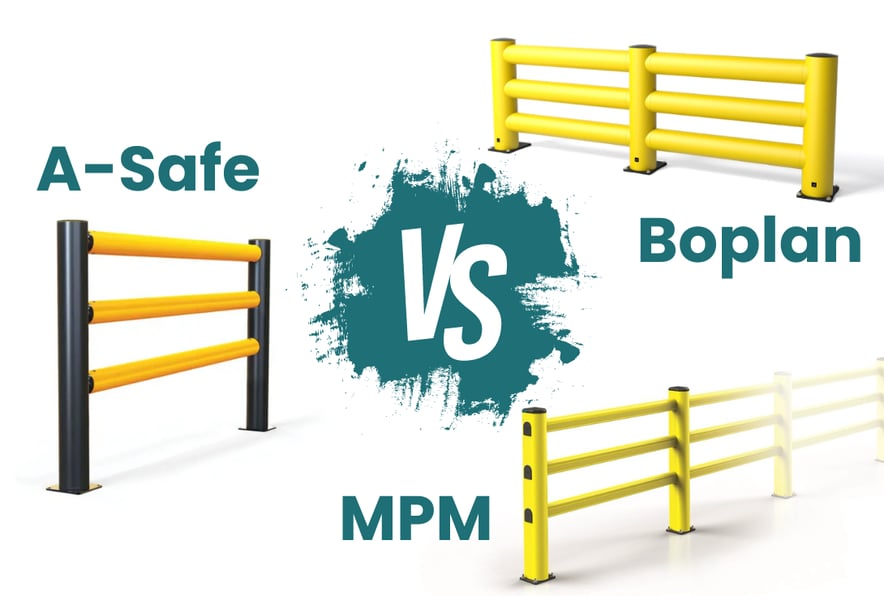

Who Are the Main Polymer Barrier Suppliers in the UK?

The UK market for flexible polymer barriers is dominated by a handful of manufacturers. Each has a slightly different approach to materials, pricing, and service.

A-Safe is the most established name. They're UK-based, with their head office and manufacturing in Halifax. Their barriers are made from HDPE (high-density polyethylene) and they offer a full range from pedestrian barriers to heavy plant protection. If you've seen yellow polymer barriers in a UK warehouse, there's a fair chance they're A-Safe.

Boplan is a Belgian manufacturer with a strong UK presence. Their FLEX IMPACT range is also made from HDPE and offers similar impact ratings to A-Safe. Boplan tends to be popular in industries with strict hygiene requirements because their barriers are chemical-resistant and easy to clean.

Clarity supplies and installs polymer barrier systems made from modified PVC rather than HDPE. This is a significant difference - more on that shortly. Clarity also offers a full warehouse safety service, including site audits, LED projected floor markings, and ongoing support from barrier safety specialists.

Rite-Hite is a US-based company better known for loading dock equipment, but they've expanded into polymer barriers with their GuardRite range. They're worth considering if you're already using Rite-Hite products elsewhere in your facility.

McCue and Brandsafe also operate in the UK market, though they tend to focus on specific sectors like retail and logistics rather than general industrial applications.

How Do the Barrier Materials Compare?

This is where things get interesting. While A-Safe, Boplan, and Rite-Hite all use HDPE, Clarity's barriers use modified PVC. The difference matters more than you might expect.

HDPE barriers (A-Safe, Boplan) are flexible, durable, and corrosion-resistant. They've been the industry standard for years and perform well in most industrial environments. The material absorbs impact and returns to shape, which is why polymer barriers outlast steel alternatives.

Modified PVC barriers (Clarity) take this a step further. The material can be up to 400% stronger than HDPE, which allows for slimmer profiles while maintaining equivalent impact resistance. This is particularly valuable in tight spaces where every centimetre counts.

If you're curious about what happens when barriers are put to the test, we've covered this in detail: Why Some Polymer Barriers Fail Under Forklift Impact.

Modified PVC also achieves fire resistance class V0 (self-extinguishing), which matters in environments where fire risk is a concern. And unlike round-profile HDPE barriers, the flat-faced rail design we supply prevents forklift forks from riding over or under the barrier - a common cause of damage with other systems.

There are trade-offs, of course. HDPE barriers typically have a lower upfront cost, and if you're already using A-Safe or Boplan, mixing systems can create compatibility issues.

What About Service and Support?

Here's something the brochures don't always tell you: the barrier itself is only part of the equation. How quickly can you get a quote? Who handles the installation? What happens if something goes wrong?

We've heard from facilities managers who've waited weeks for quotes on straightforward projects. That kind of delay can stall safety improvements and leave your team exposed to risks that could have been addressed sooner.

At Clarity, we guarantee quotes within 48 hours. Our team includes specialists who can advise on PAS 13:2017 compliance, impact ratings, and how barriers integrate with other safety systems like LED projected floor markings.

We also publish transparent pricing guides - something that's surprisingly rare in this industry. Most suppliers require you to go through a lengthy consultation before revealing costs. If you're comparing options, that lack of transparency can make the process slower and more frustrating than it needs to be.

Not sure what questions to ask when vetting suppliers? Our guide on How to Spot a Barrier Supplier Who Can Actually Audit (and Why Many Can't) covers the red flags to watch for.

How Do I Choose the Right Supplier for My Facility?

The best supplier depends on what matters most to you. Here's a simple framework:

If brand recognition and established track record are your priority, A-Safe is the safe choice. They've been doing this longer than anyone else, and their products are proven across thousands of UK installations.

If you need barriers for hygiene-critical environments like food production or pharmaceuticals, Boplan's chemical resistance and easy-clean surfaces are worth considering.

If space is tight, fire resistance matters, or you want the lowest total cost of ownership, the modified PVC barriers that we supply offer advantages that HDPE systems can't match. The slimmer footprint and higher strength-to-size ratio make a real difference in confined areas.

If service speed and pricing transparency matter, it's worth asking each supplier for their response time commitments and whether they'll share pricing before a formal consultation.

Under the Workplace (Health, Safety and Welfare) Regulations 1992, employers have a duty to provide adequate separation between pedestrians and workplace transport. Getting this right isn't optional - the HSE investigates serious injuries and fatalities caused by forklift-pedestrian collisions every year, and fines regularly reach six figures.

Whatever you decide, make sure your barriers meet PAS 13 standards for impact resistance and are installed by someone who understands your operational requirements, not just the product specifications.

Ready to Compare Your Options?

We're happy to provide an honest assessment of whether our barriers are the right fit for your facility - and if they're not, we'll tell you. That's not a sales pitch; it's just how we work.

Request a quote and we'll get back to you within 48 hours with transparent pricing and a clear recommendation.